Solutions

From Idea to Finished Test Fixture and systems

We know testing and we understand the testing processes, the tools of the trade, and the key performance indicators that testing is judged on.

01.

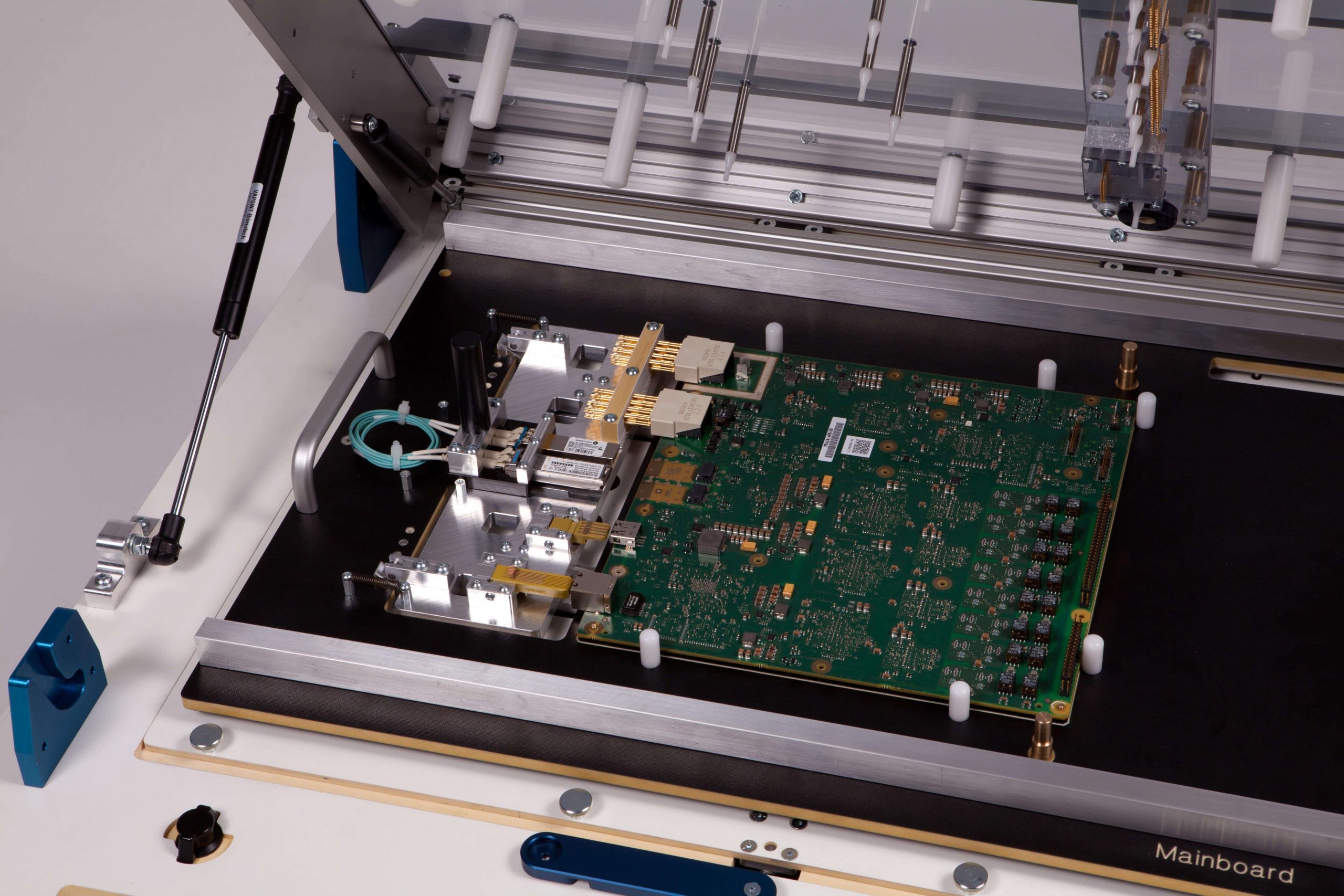

Customer Optimized Test Fixtures

We know testing and we understand the testing processes, the tools of the trade, and the key performance indicators that testing is judged on.

We also make sure to carry all different parts and bits that are needed for customization in stock. Hence our customers find us to be a reliable partner for their testing needs and together we work on making better tools, better processes, and creating better results with fewer anomalies and shorter test cycles or iterations.

02.

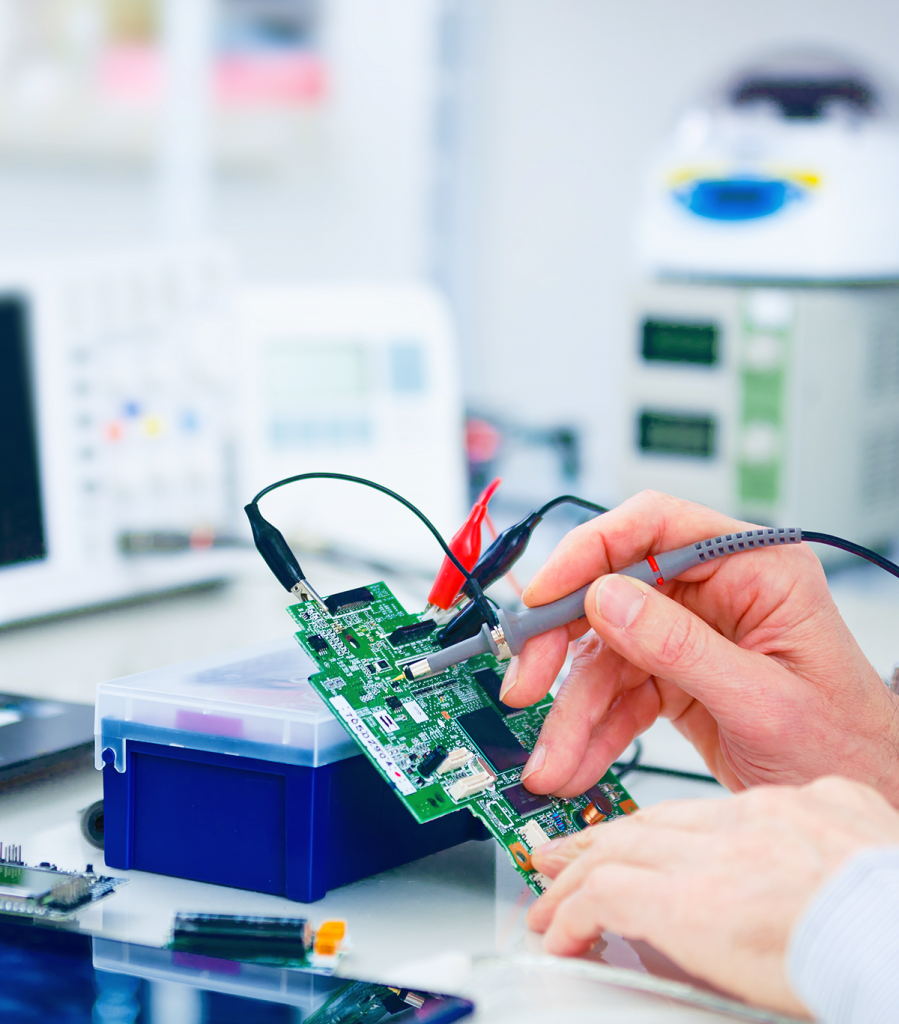

Service And Aftermarket

Columbia Kontest is well reputed for caring for its customers also after the order is signed and the solution is in place. Our support department is well sized and always ready to assist via all forms of communication.

On-site service is provided to a level specified by the customer. Columbia Kontest can match tough requirements on Response Time and Average Time to Repair.

We also provide comprehensive programmer and operator training, either on-site or at our premises. Training can be standard scheduled courses or special programs totally tailored for individual customers.

To further assist its customers towards a better focus on their core business, Columbia Kontest provides a comprehensive test programming service. Deep knowledge, based on years of experience with an impressive variety of applications, makes Kontest an ideal supplier of ready-to-go test programs.

We deliver test programs for any type of circuit board or subassembly along with necessary vacuum-actuated, pneumatic, or manually operated fixtures.

03.

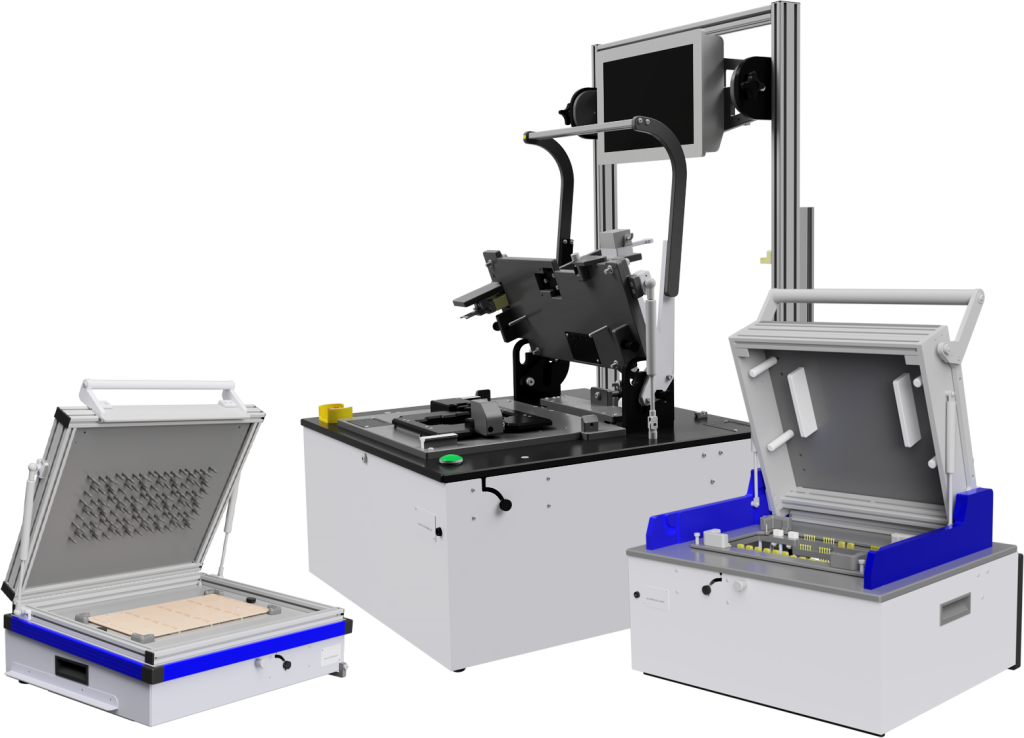

Customer-Tailored Test Systems

We offer tailored test systems and fixtures based on our experience and knowledge. Always in close cooperation with the customer!

Our software engineers also create test programs for ICT systems. This allows Columbia to supply comprehensive solutions. We also offer optical inspection AOI/SPI. By using optical inspection, defects on circuit boards are detected and one may predict errors before products reach the end customer.