We do test fixtures for mobile devices and RF/Wireless devices as well!

Regardless if you are doing production testing, quality assurance, or design verifications, our custom RF shielded test fixtures get it right every time. It allows for fast and easy development and adjustment for phone tests and works well with other manufacturing setups for mobile phone, RF/Wireless device testing.

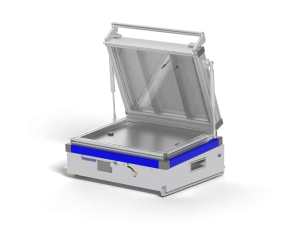

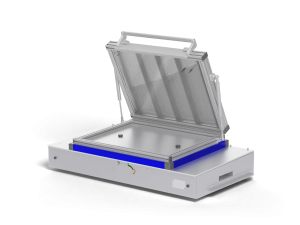

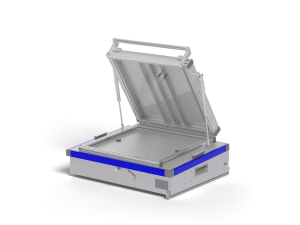

Based on many years of experience in test fixture design and fabrication – not the least for RF applications – Columbia has developed a series of test fixtures for the Bluetooth module market. The special design provides a totally shielded environment for the unit under test making it possible to perform all necessary tests under RFI-free conditions.

Production Testing

A semi-automatic, pneumatically operated fixture with a sliding pressure top provides a very short mechanical cycle-time. The unit is prepared for full, multi-station automatic operation using a centrally placed robot arm for UUT load/unload.

Lab and Prototype Testing

This small device is a manually operated fixture for accessing a single Bluetooth module. Featuring the same RFI-shielding properties as Columbia’s larger fixtures, it is ideal for initial testing during product development.