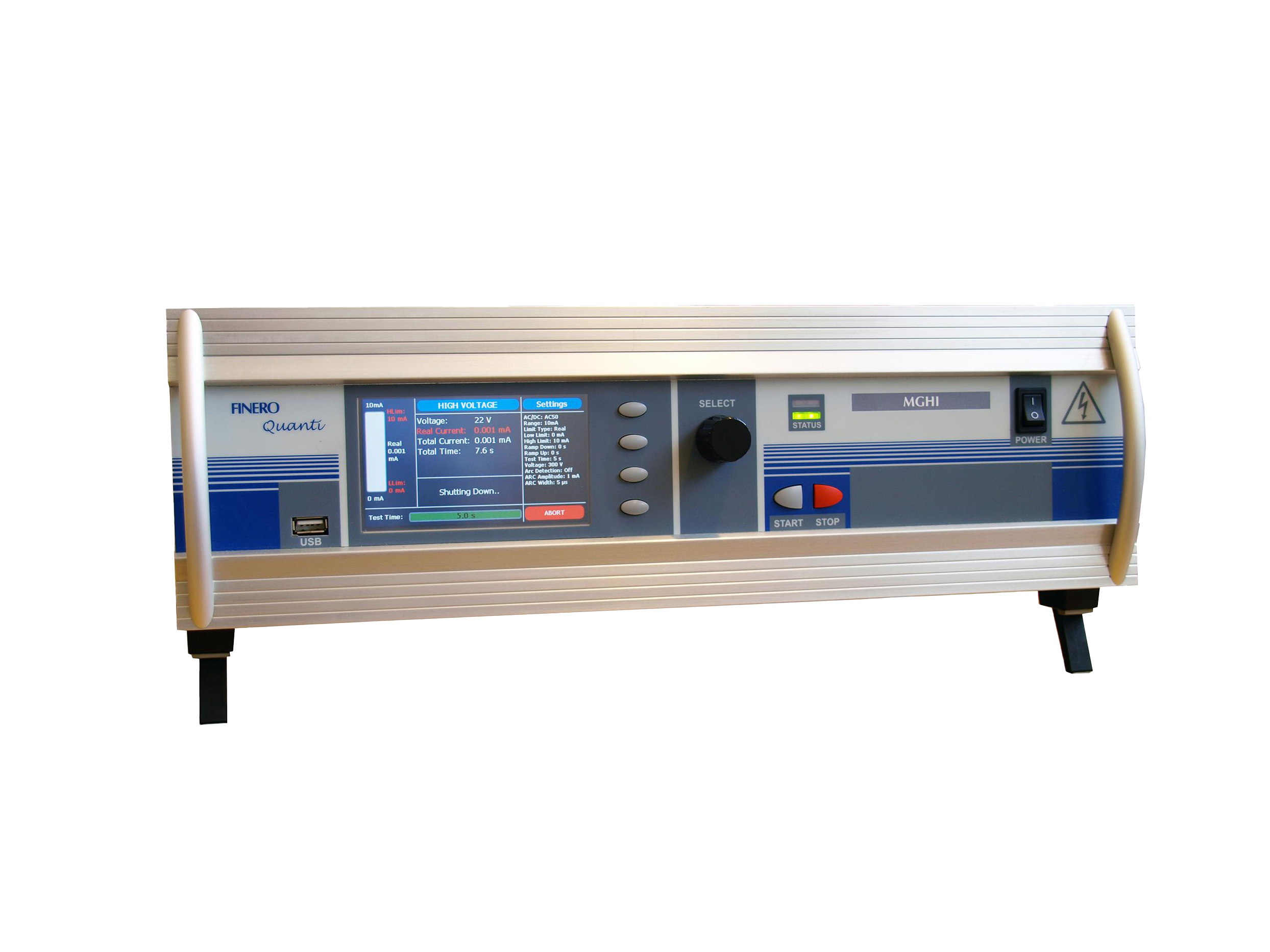

Quanti Product Series

Quanti™ lifts test and measurement and electrical safety testing to a completely new level. Quanti™ offers reliable, rugged, fast, accurate, intrinsically safe, and easily programmable testing no matter what your need is.

Uniquely this product series has various options for combining and integrating electrical safety and functional test. Quanti™ offers testing equipment for a wide range of applications, such as production, type test, and R&D. Quanti™ concept enables choosing for example from a pure high-voltage tester to a combination of test functions.

The advantages of Quanti™ are unrivaled. Quanti™ offers fast testing times and reduces testing costs because you need only one device for the LCR, DMM, electrical safety, and functional testing. Power factor correction in the input ensures that the EMC-network problems are mitigated. Despite the great variety of available test functions, devices remain very compact.

Needless to say, Quanti™ continues the Finero philosophy in building T&M systems. Quanti™ products can be equipped with four different optional interfaces. Contrary to nearly all testing devices available on the market, Quanti™ equipment uses a proprietary RS-485 interface for Quanti™ to Quanti™ communication, which enables linking of several devices to each other. This means less cabling and fewer space requirements.

There is program storage for 20 test sequences with 25 steps. The included Windows software allows the creation and loading of test programs on your PC. Like all Finero’s testers, Quanti ™ products are LabVIEW compatible.

Information and data provided can be seen on the multiple lines, crystal clear color LCD – display and the clear commands make the software easy and intuitive to use.

Comfortable menus make sure that the operator can adjust all test parameters very easily.

Quanti™ features:

- Just one or a number of tests –Quanti™ has it all!

- 4.3” LCD graphical color display

- 3U size, table, or rack-mounted

- Can be used in a wide range of applications in production, type test, and R&D

- Comfortable to adjust test parameters

- Network friendly – PFC integrated

- LabView compatible

Product Family Testing:

High Voltage

Hipot test or also called Dielectric Withstand test verifies that the insulation of a product or component is sufficient to protect the operator from electrical shock. In a typical Hipot test high voltage is applied between a product’s current-carrying conductors and for instance its metallic chassis. Hipot equipment measures extremely low currents like from microamps to milliamps.

Insulation Resistance

The insulation resistance test is one of the tests that are required by the electrical safety testing standards. The test measures the insulation resistance of a Device Under Test (DUT), while phase and neutral are short-circuited together.

Ground Bond

Ground Bond test (also referred to as PE resistance test, ground continuity test) determines whether the safety ground circuit of the Device Under Test (DUT) can adequately handle fault current if the product should ever become defective. The measured resistance has to be lower than the indicated limit from the applicable international standards. Usual values are <500 mΩ.